DAT300

Automated application of pasty 1-component products

The DAT 300 is designed for the dosing and application of pasty 1-component products and adhesives such as PUR’s, hybrids, silicones, PVC. The installation doses very precisely small shots, but can be used for continuous extrusion as well.

- Published in Automated

DBM020/200

Manual or automated application of 1-component low/hot melt glues

The DBM range was developed to process the regular hot melts and innovative reactive low/hot melt glues with the necessary safety precautions.

DHA100

Automated application of 1-component glue in car window holders

The DHA100 is developped specifically to apply a high viscous 1-component glue into holders. Holders are plastic parts which are fixed to the bottom of the electric side car windows. They connect the window with the small motor causing the windows to move up and down.

This installation, equipped with a simple dosing system, ensures the application of a repetitive shot quantity, avoiding extra cleaning steps to remove excessive glue. The holders can be placed directly onto the window after glue application.

- Published in Automated

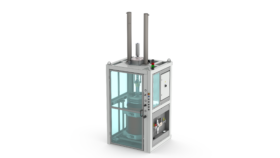

Hydraulic pumping unit

The DRU is a hydraulic pumping unit for high viscous products ,developed by Delta Application Technics. It meets the safety requirements to ensure a safe work environment for your operators.

- Published in Automated