Automated solutions

If you have any questions or if you would like to receive further information, contact us or fill out the contact form at the bottom of this page.

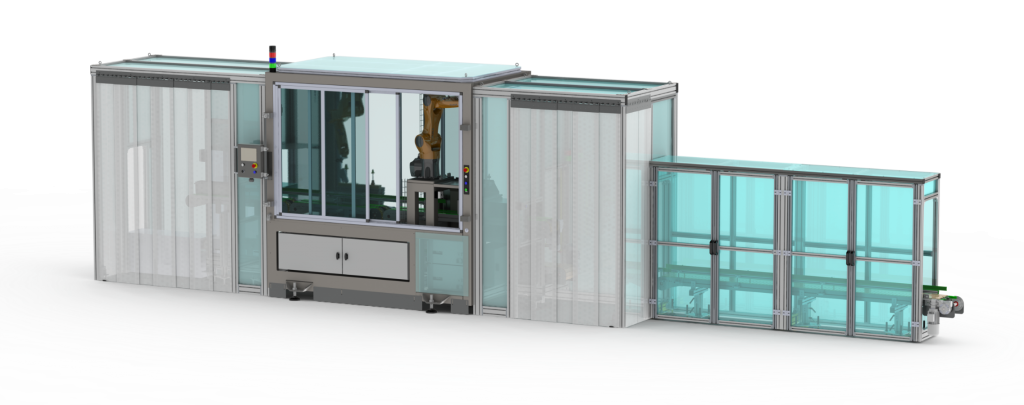

Automated solutions for application of adhesives engineered to ensure precise and accurate dosing of the product. This contributes in repeatability and a constant, controllable production process.

Surface pre-treatment and dosing

Plasma pre-treatment and dosing of a 2-component MMA glue on composite parts

The 2 parts are manually cleaned and put on a conveyor. After pushing “start”, both parts enter the installation, where they are both treated with plasma (Tigres). The glue is applied to the lower part. Both parts exit the installation to be manually assembled.

Automated heated glue dispensing

Semi-automatic application of a reactive low melt glue onto ceramic parts

The 2 parts are loaded into the machine manually by an operator. First a dot of glue is applied on 1 of the ceramic parts, so the operator can come in and add an insert on top of the dot of glue. When the operator exits, a complete circle of glue is applied and both parts are assembled together.