All below dispensing machines can be used in automated applications

DAT050

Application of low to medium viscous 2-component products with fixed ratio

The DAT050 is an economical solution for a 2-component product with fixed ratio, designed for basic applications where there is no need for flexibility in the product ratio.

- Published in 2-component systems

DBA100

Application of high viscous 1C product + accelerator

This installation is suited to dose and apply a high viscous 1-component product together with an accelerator (max 1.3%). This accelerator is added to increase the curing speed of the additive in such a way that the bonded product can be processed further after a few seconds. The accelerator can be added on certain points or during the whole extrusion.

The dosing of the small quantity of accelerator is very precise thanks to our own developed dosing system. Depending on the ratio, the accelerator can be fed out of cartridges, pouches or pails.

- Published in 2-component systems

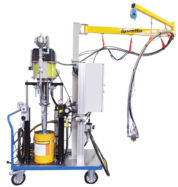

DMC022

Application of pasty or high viscous 2-component products

The DMC022 is a metering and mixing system for pasty or high viscous 2-component products. The machine is engineered for the dosing, extrusion and application of your products. Also very thixotropic products can be processed with the DMC022.

Click for more information.

- Published in 2-component systems

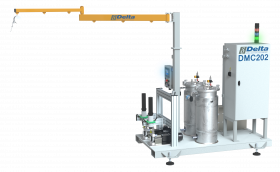

DMC202

Application of low to medium viscous 2-component products

The DMC202 system is engineered for the metering and mixing of low to medium viscous 2-component products as epoxies, polyurethanes, silicones, etc.

The installation can be used for manual or automatic applications and has different options. It’s a modular system composed according to the characteristics of the product and your needs.

- Published in 2-component systems