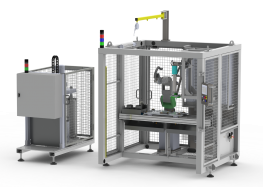

Automated solutions

Automated solutions

Automated solutions for the application of adhesives with robots to ensure repeatability and precise, accurate dosing of the product. These are engineered and produced in-house with the customer to offer a complete solution for your production process.

- Published in Custom solutions

Automatic paint application systems

Systems for automatic paint application

Thinking of automating your paint application process? Delta Application Technics can help you with a automated paint application systems to apply your solvent (ATEX) or water based paint on to your product in a correct and accurate way.

- Published in Various

Coating application systems

Systems for all kinds of coatings

Systems for coating application of low viscous products such as oils, water, fire retardant coatings, etc. Also ATEX systems are available.

If you have questions about your application, do not hesitate to contact us for more information.

- Published in Various

DAG001

1-component low flow application gun

The DAG001 is a 1-component application gun for fluid and pasty products, to extrude and apply 1-component products. Different types of adapters and extrusion/spraying nozzles are available to meet the needs of your application.

- Published in Guns/Valves

DAG002

1-component high flow application gun

The DAG002 is a 1-component high flow application gun to dispense 1-component products such as adhesives and other fluids.

Different types of adapters and extrusion nozzles are available to meet the needs of your application.

- Published in Guns/Valves

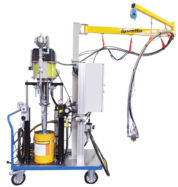

DALxx-xx

Airless spray installations

Standard airless spray installations engineered to cover a wide range of applications.They can be used to spray higher flows of paints, varnishes, etc.

For more details, contact our sales team.

- Published in Airless spray

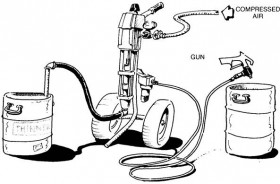

DASxxx

Airspray installations

Spray installation systems to apply paints, adhesives and other low viscous fluids by means of air atomization. They can be used manually to fully automated, according to your needs and production process.

Contact our sales team for more information.

- Published in Airspray

DAT050

Application of low to medium viscous 2-component products with fixed ratio

The DAT050 is an economical solution for a 2-component product with fixed ratio, designed for basic applications where there is no need for flexibility in the product ratio.

- Published in 2-component systems

DAT300

Automated application of pasty 1-component products

The DAT 300 is designed for the dosing and application of pasty 1-component products and adhesives such as PUR’s, hybrids, silicones, PVC. The installation doses very precisely small shots, but can be used for continuous extrusion as well.

- Published in Automated

DBA100

Application of high viscous 1C product + accelerator

This installation is suited to dose and apply a high viscous 1-component product together with an accelerator (max 1.3%). This accelerator is added to increase the curing speed of the additive in such a way that the bonded product can be processed further after a few seconds. The accelerator can be added on certain points or during the whole extrusion.

The dosing of the small quantity of accelerator is very precise thanks to our own developed dosing system. Depending on the ratio, the accelerator can be fed out of cartridges, pouches or pails.

- Published in 2-component systems